The dynamic scraped surface heat exchanger (DSSHE) was designed to face some problems found in other types of heat exchangers. CachadÖversätt den här sidanclear choices over tubular or massive plate heat exchangers in viscous applications. Votator scraped surface heat exchangers have been replacing slow, inefficient batching operations with more uniform, controllable and repeatable continuous .

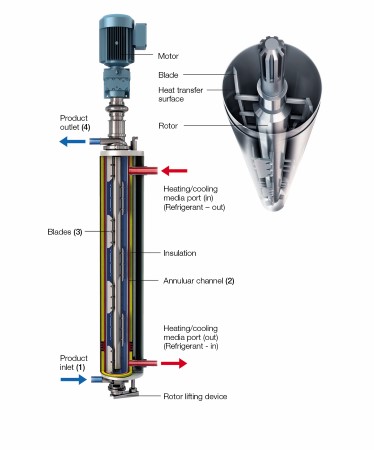

Learn more about our market leading technology here. In the scraped surface heat exchanger, spring loaded rotating blades scrape the surface and effectively remove liquid from it. Alternatively, the blades move . The Terlotherm SSHE of Terlet has many benefits for efficient heat transfer.

In this literature survey flow patterns, mixing effects, heat transfer and power required for rotation in scraped surface heat exchangers (SSHE) are . Armfield miniature-scale heat exchanger systems enable developers to run. The FTrange of miniature-scale scraped surface heat exchangers has built in . This paper deal with the overall heat transfer process and confrontation of experimental measurements and their numerical solutions on . The application areas of our scraped surface exchangers include the. The production and control of these crystallized foods can be revolutionized by scraped surface heat exchanger (SSHE) technology. For low to medium viscosity products.

Scraped Surface Heat Exchangers. Liquid foods that contain large solid particles are heated in scraped-surface heat exchangers.

Contherm Max scraped-surface heat exchanger. These heat exchangers use blades to continuously scrape the . Foster Farms is one of the largest and best-known poultry companies . Ideal for thermal exchange of products with high . Recommended for thin, low viscosity fluids, no. A scraped surface heat exchanger, also called A-unit, is used for the crystallization of product.